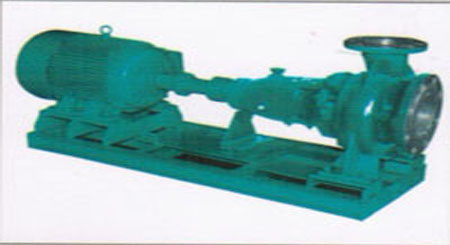

ZH, ZHA Petrochemical Process Pump

Category:petrochemical pump

- Clicks:

- Release date:2014/05/06

- Online Inquiry

ZH, ZHA pump for conveying clean or contain particles of liquid, low or high temperature liquid, neutral or corrosive liquids.

Main purposes:

1, oil refineries, petrochemical industry, coal processing industry and cryogenic engineering.

2, the chemical industry, paper and pulp industry, sugar industry and the general process industries.

3, heating and air conditioning systems, environmental engineering, marine and offshore industries.

4, water plants, desalination plants, power plants.

Performance range:

Diameter 25 ~400mm

Flow (Q) up to2600m3/ h

Head (H) up to250m

Working pressure (P) of up to 2.5MPa

Temperature (T) -80 ~ +250 ℃(ZH-type pump)

-80 ~ +450 ℃(ZHA-type pump)

Structure:

ZH, ZHA pump is single stage, horizontal cantilever centrifugal pump, ZH-type pump for the foot support. ZHA-type pump for the center bearing, single-suction impeller radial, axial suction and radial discharge.

Depending on conditions, the use of front and rear wear rings and balance holes for hydraulic balancing. Stuffing box with cooling or heating fittings. Seal with packing seal can also be single face or double mechanical seal. And is equipped with cooling, flushing or sealing liquid system. Standard piping design according to API610 specifications. Suction and discharge flange of the same nominal pressure rating. Looking from the motor pump is clockwise.

6 using self-lubricating bearing lubrication (oil ring) or forced lubrication.

7 static metal sealing surface sealing, wound pad seals and "O" ring seal.

8 dynamic seal for mechanical seal, wash rinse cycle way from, outside tap and rinse washing three ways.

Related Tags:PetrochemicalPump

Related Products:

Related News:

- Low pressure petrochemical pump pipe USES

- Petrochemical pump pitched battles in the high-end market

- In 2020, our country will become the worlds largest petrochemical pump importer

- 12 years in southern Europe pump industry organize seminars will be held in Switzerland

- The working principle of petrochemical pump

- China petrochemical pump and larger development space

- General petrochemical pump machine in the second half of the export growth decreases

- Petrochemical pump type and significance

- Implementation of Egypt petrochemical pump produced independently

- South Korea NARA speed control type hydraulic coupler